PHD DEVICES is proud to introduce their newest device, tailored to meet the needs of the Fuel Additive Industry but perfect for any application that requires volume-based dosing.

Revolutionizing the Fuel Additive Industry…

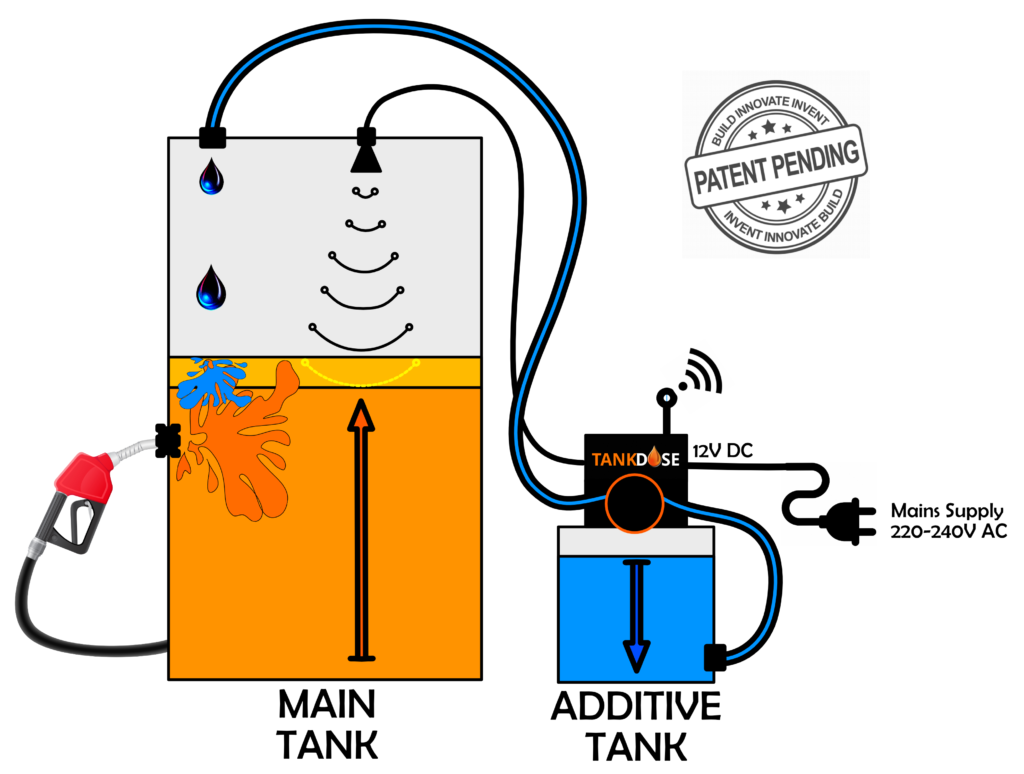

TANKDOSE is an Automatic Volume-Based Dosing Device with IoT capability, allowing data to be remotely monitored using a WebApp. It utilizes an Ultrasonic or PROGAUGE sensor and positive displacement pump. It is able to achieve volume ratios of 0.001%, which is unheard of in the industry.

TANKDOSE can administer a fuel additive automatically, which in-turn, can help to keep the tank free

from algaecides, prevent corrosion occurring, elongate the storage lifecycle of the fuel and create efficiencies of up to 8%, thus helping to lower emissions.

Other products in the marketplace use time-based, flowrate and blending solutions, which require constant flow. Even with pulse-width modulation, these devices can only achieve ratios of approximately 2%. This is insufficient for most premium additives that require much lower ratios.

TANKDOSE solves these problems and more.

CONTACT US FOR A FREE DEMO

The Main Tank has an ultrasonic or ProGauge sensor, which detects the level of the liquid in the tank.

When the liquid level increases, TANKDOSE calculates the change in volume for every millimeter, and in-turn triggers a pump, which doses the user-defined ratio of additive into the Main Tank, where it is mixed with the incoming stream.

PRE-SALE ON NOW!

LIMITED STOCK AVAILABLE FOR EARLY ADOPTERS

BE QUICK – 12months FREE software subscription.

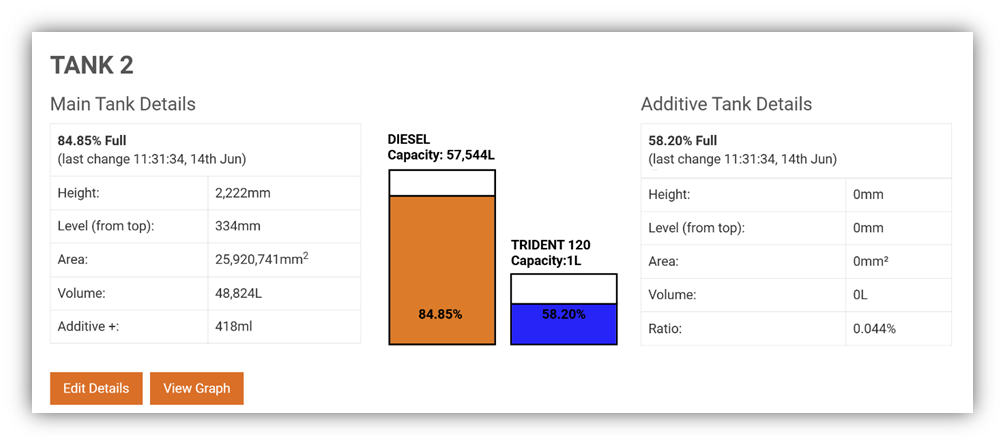

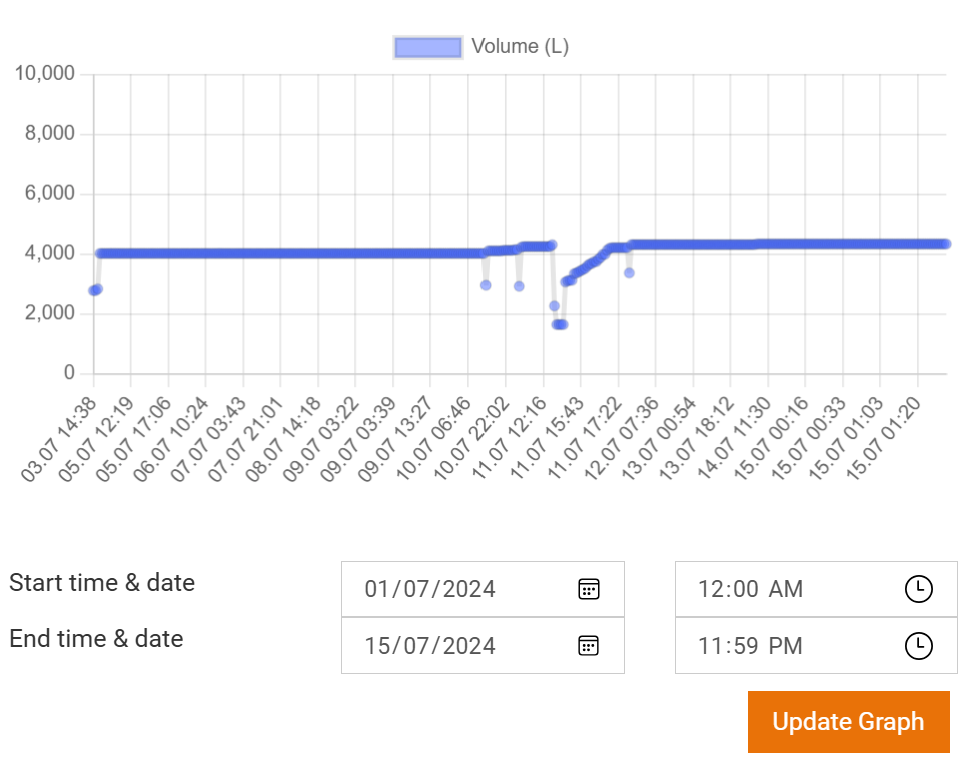

TANKDOSE is an IoT device that will give the user full visibility of their additive usage, through a WebApp. The user can monitor the volumes in their tanks remotely, saving valuable time and minimizing waste.

The WebApp can be accessed from a phone, iPad, PC or any device with internet access, by visiting www.tankdose.com.

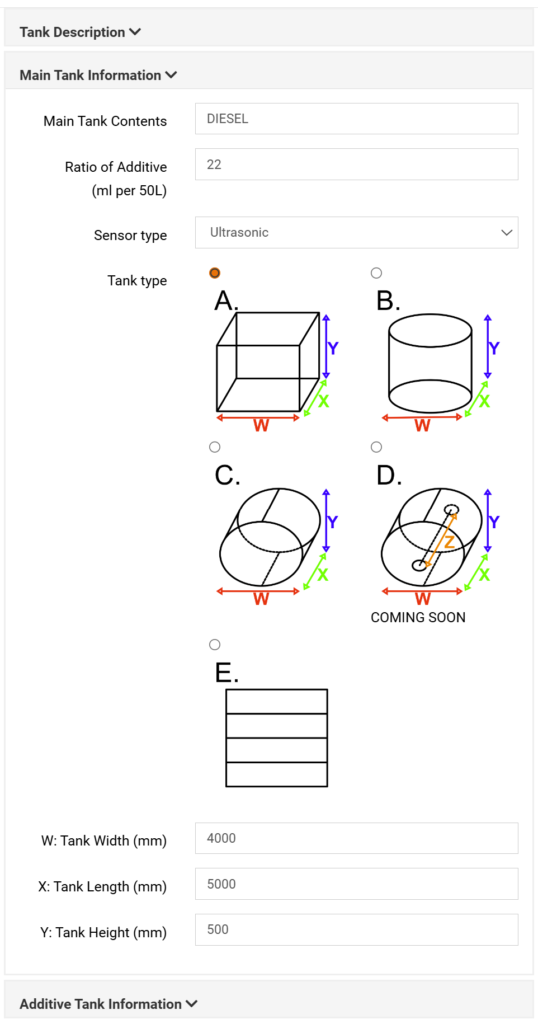

If a user has a large Additive Tank, they may wish to connect an ultrasonic sensor to that tank also. The configuration can be entered in the same manner as the Main Tank. This gives an accurate account of the remaining additive. However, it is also possible to select no sensor, for the Additive Tank, and instead enter a refill value. This value is then used, instead of the calculated value, to notify the user when the additive is running low.

For our 4 known container shapes, there is no need for a strapping table/calibration chart, as this is calculated within the device. However, if connected to an unknown shaped tank, a strapping table/calibration chart can be uploaded via the WebApp.

If you are looking for an automatic dosing solution for your fuel additives, TANKDOSE is for you!